Proper Management is a vital key to a profitable poultry production business and an essential component of these is proper litter management. Every farmer willing to succeed in this business most find a way to master the act of proper liter management because it is the pre-cursor of many diseases on the farm but many farmers in Nigeria do not take it with the seriousness its deserves.

Poultry litter is a mixture of poultry excreta, spilled feed, feathers, and material used as bedding in poultry operations. This term is also used to refer to unused bedding materials. Poultry litter is used in confinement buildings used for raising broilers, pullets, turkeys, cockerel and other birds. Birds raised on free range do not need to be provided with litter as they can easily roam about and move freely without any form of restriction. Common bedding materials include wood shavings, sawdust, peanut hulls, shredded sugar cane, straw, and other dry, absorbent, low-cost organic materials and processed paper. Sand is also occasionally used as bedding though not a good practice. The commonest ones in Nigeria is wood shavings because of its availability all through the year and the relatively cheap its command – it’s even free in many rural farming communities.

Litter is an essential component in poultry production, because birds are exposed to the litter and its contents (microbes, moisture, ammonia, dust, odour, and texture) from the first day of life till cull or slaughter. It is instructive to note that Badly managed litter may and will facilitate the spread of certain infectious diseases, and also creates problems which may lead to serious economic losses on the part of the farmer. The “litter problems” have not yet been classified or identified specifically, since they are connected with other management problems as well. In essence, it may be difficult to strictly point to different types of litter problem in terms of classification because it is an all inclusive causality issues ranging from management to others.

IMPORTANT FACTORS TO CONSIDER IN LITTER MANAGEMENT

1. Litter Moisture Content

Moisture play a significant role in litter management, in fact moisture is number factor in litter management. When litter begins to retain moisture it will clump together, which is referred to as caking. Why dry litter begins to cake is often misunderstood, but it is not complicated. Too much moisture within a poultry house can cause litter to cake. It is just that simple. However, it takes a long time (days and in some cases, maybe weeks) for moisture levels in the litter to build up enough for cake to form. Moisture can build up because the ventilation rate within the house is inadequate over a prolonged period (not just a few hours). The way water is being managed within the pen facility is also key to the state of the litter.

Once litters begins to cake, it is difficult to reverse the process. It usually requires over-ventilation to correct the problem, which can lead to excessive gas use during cold weather and high energy costs year-round. The most effective way to get rid of a cake litter in these part of the world especially in Nigeria with poorly developed machines and tools is to regularly evacuate it periodically by the attendants. As expected Caked litter also increases house ammonia levels. Poultry are most susceptible to elevated ammonia levels at one to 21 days of age, which is the early brooding period. Adequate ventilation, Periodic evacuation and use of litter amendments are few practices that help control ammonia volatilization within the poultry pen house. Unfortunately, farmers often underestimate ammonia levels if they depend on their eyes and noses for detection. Most farmers become somewhat desensitized to ammonia after long-term exposure, making it difficult to accurately gauge ammonia levels in their houses. This can result in decreased bird performance and serious welfare issues in both man and animals.

Litter moisture is the key to the burnt hock problem in birds kept on deep litter. It is unusual for there to be burnt hocks when the litter condition is friable and dry. Litter moisture is also affected by drinker designs, air change rate within the facility, state of litter material and depth, the stocking density of the birds, Nutrition and general flock health. Wet litter causes degeneration of the outer scales on the hocks and feet (the pressure points). As live weight increases and mobility decreases the pressure becomes greater and contact with the litter more prolonged. Males are therefore more affected by wet litter than females due to their size and activity.

2. Housing and management

The type of house and design of the poultry pen is very important in litter management. Houses with concrete floors may be easier to clean, but those with earth floors are more difficult to handle and disinfection following removal of old wet litter may be an ineffective procedure, leaving infectious materials and debris. This will become a source of infection when new broods of chicks are placed in the house. And this could be passed from one flock to the other especially if adequate cleaning is not done. When preparing house for a new flock, it is important to thoroughly scrub and disinfect the existing pen so that pathogens from one flock is not passed on to the other.

Some houses seem to have a continuous problems with wet litter. Poorly constructed houses, especially where roofs are not properly insulated, can lead to condensation which drips on the litter. Such a problem may also arise from worn nipples that have been used for several years or more without changing. The timely replacement of worn nipples should, therefore, provide an opportunity for improving litter quality. Reductions in cake volumes of 50-90% are reported following replacement of worn nipples. Other management opportunities include pressure adjustment, proper line height, and routine flushing and line sanitation. When excessive caking develops under drinkers, it may be necessary to totally remove them and top it with fresh, dry bedding to prevent disease outbreak especially Coccidiosis.

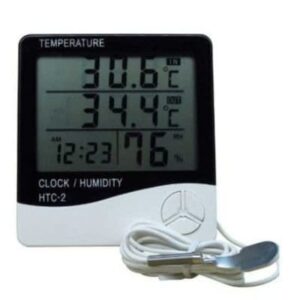

3. Temperature and humidity

For big farms that are involved in commercial broiler production, Fans, not optimally numbered or located, or running at incorrect rates may allow poor gas exchange at certain points in the house. This helps water vapour to be absorbed into the litter or not to escape from it. Consequently, mould and bacterial growth is enhanced, particularly when the in-house temperature is high. Poor ventilation, along with the high temperature and humidity, may also lead to ammonia build-up in the house. This may reach noxious levels which are unpleasant for attendants and the stock. In severe cases, ammonia build-up will contribute to various disease problems such as coccidiosis, breast blisters, ammonia burns, and other respiratory infections within the flock if not adequately addressed.

Good litter and air quality can be maintained with proper ventilation but it has to start when the previous flock goes out and continue throughout the new flock. The trick is to stay one step ahead while being as efficient as possible. No one wants to over-ventilate with high fuel prices and energy consumption, but under-ventilating can be even more devastating when it results in lost performance, health concerns, and welfare issues among the flock. Keeping litter in good condition and avoiding caking are extremely important because of the high cost of loses wet litter may cause, and because disposal of this litter is becoming more of an environmental issue especially in farms that are in close proximity to communities .

In order to ensure healthy and profitable broilers, Farmers must maintain dry litter. Wet litter greatly increases pathogen load and, therefore, chances of a disease outbreak that may require a total clean-out. However, barring a major disease challenge, some poultry complexes never require a complete clean-out, but rather only need close management of litter depth to keep above aboard.